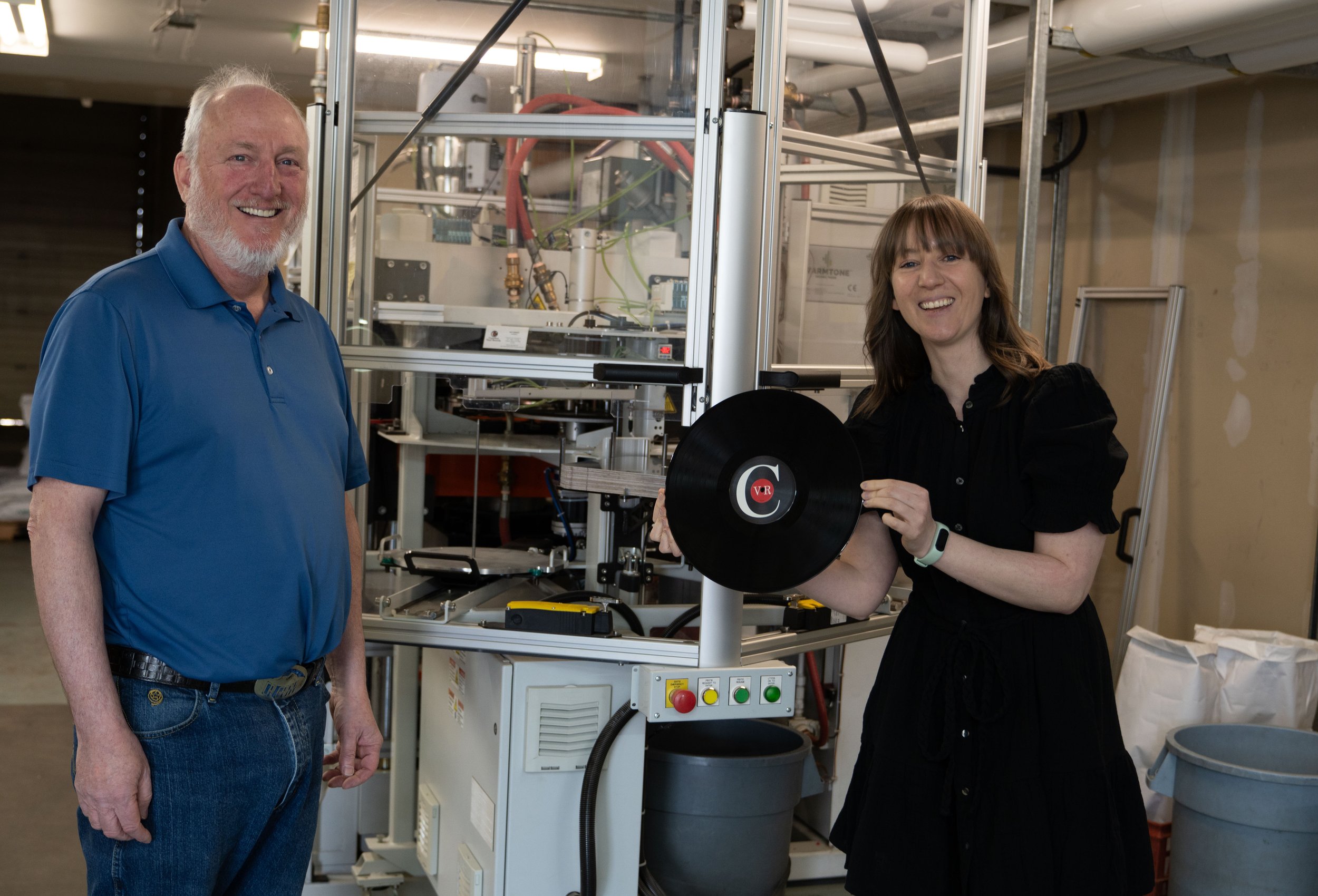

Meet the Lawsons: The father-daughter duo keeping vinyl pressing alive in Calgary

Ian Lawson, 66-year-old Calgarian entrepreneur is photographed with his 34-year-old daughter Sarah Lawson, at the Canadian Vinyl Records office in Calgary, on March 18th 2025. This father daughter duo is keeping the record pressing business local.

Canadian Vinyl Records, founded in 2017 by Ian Lawson, is a Calgary-based record manufacturer. The business launched when local artists were scrambling to find a pressing plant.

Before Canadian Vinyl Records, local artists relied on Canada Boy Vinyl—until they couldn’t.

Canada Boy was overstaffed, its machines were old, and with about $66,000 owed in rent and a handful of angry customers, the company shut down in 2015.

The warehouse where Canada Boy had their pressing plant is owned by Ian Lawson.

“After about two years and $2.5 million, they realized it wasn’t working,” said Lawson.

Ian Lawson understood the business itself was not a bad idea, management was simply not good.

“I did a very careful analysis, and decided that's going to work,” he said.

He replaced old, inefficient equipment, including presses and a boiler to transform this space into a state-of-the-art pressing plant. He even introduced a greener alternative for the cooling process, he said.

The pressing plant that once ran with 14 employees, now operates with two: Ian and his daughter Sarah.

Together they produce the highest quality vinyl for many local artists.

Sarah describes working with her father as a great experience. They have a good rhythm and share a passion—making a difference in a big industry.

“I feel like I'm supporting local in this massive industry that really is global. I'm making a difference just here in Calgary,” said Sarah.

This father-daughter duo came into the scene at the right time and has managed to overcome the effects of COVID and big labels setting up their own pressing plants.

So what goes into pressing the perfect record?

It all starts with a digital file that gets cut into a set lacquer (side A and side B). Lacquers are made of aluminum which then gets plated to make a strong stamper.

PVC pellets are melted into a “puck,” which is pressed between the stampers and labels.

Water cools it off and it gets placed into the trimmer to remove the excess from the edges and get that perfect, round shape.

After it’s cut, it goes onto a spindle where cooling plates help ensure the records set perfectly flat.

The whole process takes about 30 seconds from beginning to end once the press is warmed up.

The Lawsons check the records to make sure they don’t come out looking like “cowboy hats” and that the weight is right.

Their attention to detail is one of the many things that sets them apart in this busy industry.

“We're making a really high quality product that accurately reflects the amount of work, the knowledge and the skills of the artists. It's very rewarding. At the end of the day, I go home and feel like I've done something good,” said Ian Lawson.